- Fastening Solutions

- Industries

- Why Field

- About

- Resources

- 815-637-9002

- Fastening Solutions

- Industries

- Why Field

- About

- Resources

- 815-637-9002

- Careers

- Suppliers

- Contact Us

- IFI Connection

- Search

What is ASN? An Advanced Shipping Notice (ASN) is a digital document that offers comprehensive details about an upcoming delivery. Commonly used in supply chain management, ASN acts as an alert from the sender to the receiver, notifying them of an incoming shipment and providing specifics about its contents. Challenge Customer's accounting and receiving departments were spending an excessive ...

Read More

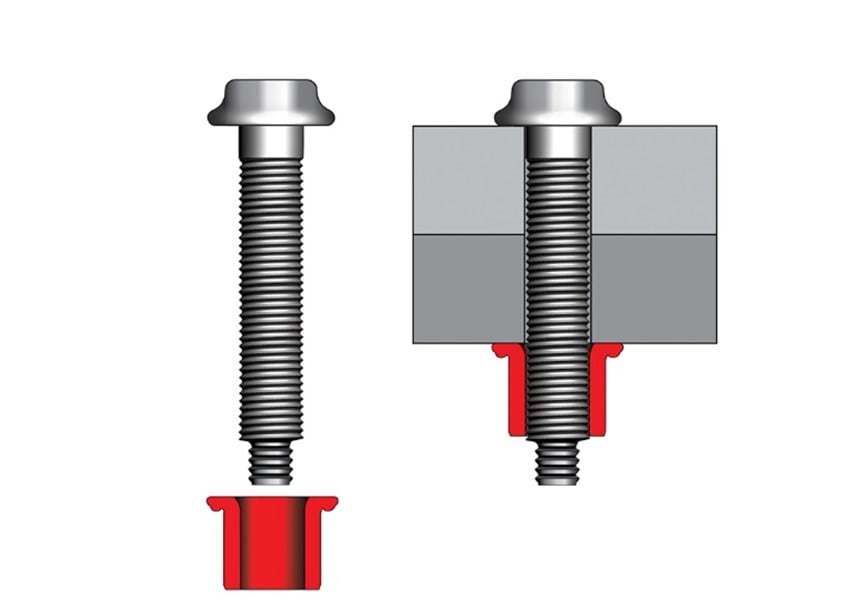

Huck pin and collars offer one of the most robust ways of ensuring your joints don't come loose in service, but are you looking for an opportunity to improve operator safety while reducing your Huck spend? Challenge The C50L has a designed break in the pin, the broken off portion can end up on the floor causing safety issues for the operators. The noise level and jolting motion created by the pin ...

Read More

Huck Pin and Collars offer one of the most robust ways of ensuring your joints don't come loose in service, but are you looking for an opportunity to reduce your Huck spend? Challenge We see Huck pins offered in many different plating options, the most common are zinc plated GA and GA2X code to 72 hours and 1,000 hours of corrosion resistance per ASTM B633. In many cases these pins are installed ...

Read More

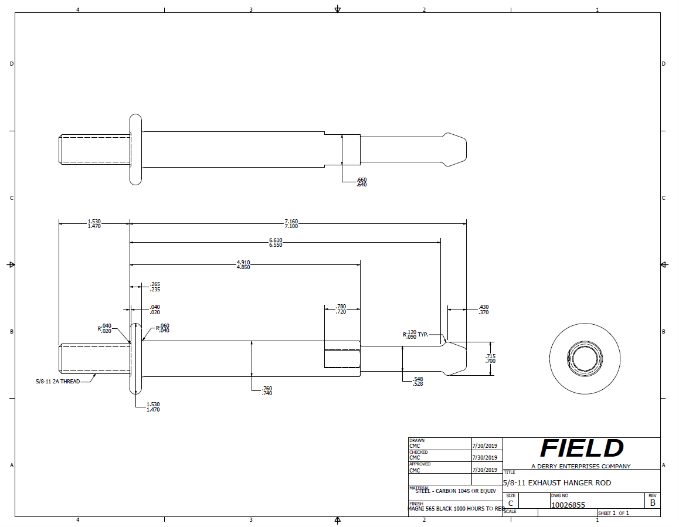

Industry feedback is that searching for existing parts in a system can be more of a challenge and more time consuming than designing a new part. Field developed a tool in efforts to drive down SKU's. Rather than spending time designing parts that might be very similar to existing designs, our customers can utilize our tool to help search for the parts they need. By understanding what parts are ...

Read More

THE FIELD ENGINEERING TEAM PROPOSES ALTERNATIVE MANUFACTURING PROCESS TO ADDRESS QUALITY ISSUES WITH CURRENT DESIGN.

Read More

THE FIELD ENGINEERING TEAM PROPOSES ALTERNATIVE MANUFACTURING PROCESS TO ADDRESS COST ISSUES WITH THE CURRENT DESIGN.

Read More

The Field engineering team proposes alternative system to address short comings of current design while creating 9.5% in savings. Challenge During a technical line review at a prospective customer’s facility, Field noticed high volume parts with features that were driving the cost up. The thread cutting screws being used required a secondary operation to create the slot. During assembly, the ...

Read More

FIELD PERFORMED AN ANALYSIS OF THE TOP 10 HIGHEST REVENUE PARTS TO FIND COST DRIVING FEATURES Challenge When reviewing the top 10 highest revenue parts from a customer, Field noticed that there were certain features on the parts that were significantly driving costs up. In an effort to be more than parts, Field’s engineering team came up with alternatives to design out those cost driving features.

Read More

FIELD HELPS CUSTOMER REPLACE CRIB STYLE REPLENISHMENT SYSTEM

Read More.png)

Challenge Field received a request from a prospective customer that provides components to the automotive industry. The request was for two high volume components that are utilized to fasten several components in a passenger vehicle. The requested design was a high cost / proprietary design.

Read More

During a technical line review at a prospective customer’s manufacturing facility, the Field engineering team observed inefficiencies with an assembly process. Here's how we helped solve them.

Read More

Observations and Solutions During a technical line review of a customer’s facility, the Field team observed the components and methods of manufacturing used to assemble a railcar. The following observations were made with corresponding solutions:

Read More