During a technical line review at a prospective customer’s manufacturing facility, the Field engineering team observed inefficiencies with an assembly process. Here's how we helped solve them.

Challenge

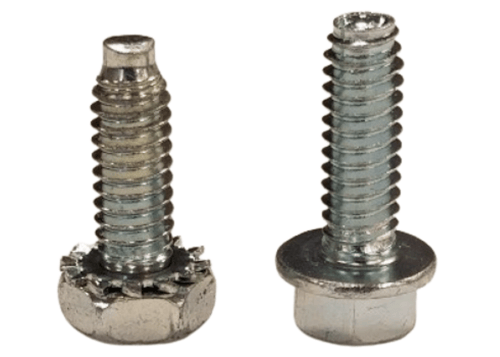

The application in question involved tightening a SEMS dog point machine screw into tapped t-nuts with metal brackets/framing acting as the clamped component. The primary source of the frustration came from the challenges associated with cross-threading, scrap & rework and poor ergonomics. These challenges ultimately lead to a cumbersome manufacturing process viewed as an opportunity to further cater towards a DFM/A philosophy.

Solution

The Field Engineering Team came up with an innovative idea to design a solution that would eliminate the high cost & challenges associated with the current system.

The SEMS dog-point machine screws along with the threaded T-nut are being evaluated for replacement by an alternative joining system. By potentially using a tri-lobular thread forming fastener in an untapped T-nut we could substantially reduce the piece price, improve assembly time, and eliminate scrap & rework associated with cross threading. This could be accomplished all while maintaining or possibly improving the performance of the current joining system. Furthermore, Field’s approach of collaborating with our customers will allow us to develop a comprehensive test plan that will virtually eliminate the need for any testing done by the customer.

Validation Testing By Field

The following validation testing will be performed in order to prove out the proposed alternative fasteners:

- 600 Rundowns across 7 different applications.

- A DC electric drive tool will be used to install the fasteners.

- Torque transducer connected to an MC900 data acquisition unit will be used to measure and record torque.

- The output of this testing will be a comprehensive test report detailing comparative torque angle to failure testing.

- The output of Fields report will allow our customer to make the decision on whether or not to move forward with this project while having to do little to no testing themselves.