- Fastening Solutions

- Industries

- Why Field

- About

- Resources

- 815-637-9002

- Fastening Solutions

- Industries

- Why Field

- About

- Resources

- 815-637-9002

- Careers

- Suppliers

- Contact Us

- IFI Connection

- Search

Challenge During a plant Gemba Walk with a current customer, Field observed an assembly condition and took steps to perform an Applications Problem Solving and Assembly Line Review of their manufacturing process when applying tape to pipe plugs and pipe nipples.

Read More

OVERHAUL OF CLIENT'S VMI PROGRAM YIELDS COST SAVINGS OF $50,000 Challenge Looking to improve on-time delivery, and reduce customer involvement and time needed to manage their hardware VMI program, a prospective customer elected to engage in discussions with Field. Inefficiencies with on-site scanning and replenishment, and overall organization of the program were weak. This led to parts hoarding ...

Read More

PART REDESIGN AND PROCUREMENT IMPROVEMENT YIELDS TOTAL SAVINGS OF $206,500 The Challenge During a technical line review of a customer’s facility, the Field team worked with the director of purchasing to identify cost-reduction opportunities among high-volume parts. One element in particular drew their attention: a stainless steel window hardware part.

Read More

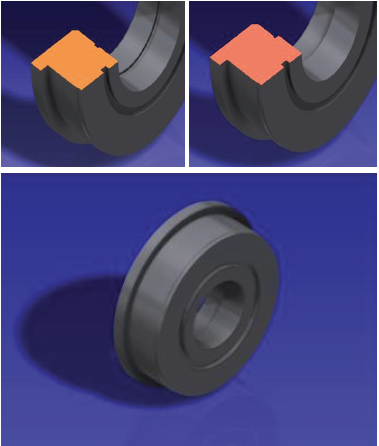

FIELD INITIATED ENGINEERING REVIEW AND PRODUCT REDESIGN YIELDS $170,000 IN COST SAVINGS Challenge Field initiated an engineering review of a customer’s application that revealed a high-cost component, which required multiple assembly steps and created potential quality concerns. Field provided engineering resources to redesign a more cost-effective part that lowered component costs, assembly ...

Read More

FIELD EXECUTED A SEAMLESS TRANSITION AND REDUCED PROCUREMENT TIME BY 90% Challenge A manufacturer of signaling devices had a muddled VMI system in place that had excessive inventory levels yet daily stock outs. The supplier had a 8,000 sq/ft in-plant store onsite that was taking up valuable production floor space. The damage included 1,500 part numbers in over 5,000 bins and 55 VMI stocking ...

Read More

FIELD REDESIGNS TOOL, YIELDS $47,400 IN SAVINGS EQUATING TO 10X THE COST OF THE FASTENER Challenge Unaware of any immediate product improvement opportunities, the purchasing manager of a prospective Field customer led the Field team onto the manufacturing floor for a technical line review of the facility. Field immediately identified a significant cost-savings opportunity at the first work ...

Read More

FASTENING REDESIGN YIELDS SAVINGS OF $44,470 MORE THAN 9X THE COST OF THE FASTENER Challenge A prospective customer approached the Field team with a request for a quote on a fastener.

Read More

Challenge During an engineering review of a customer’s facility, Field inquired about the assembly process of one of their most popular tools. During a ‘Fit, Form and Function’ analysis of the tool back in the Field lab, cost saving opportunities were immediately identified.

Read More

REDUCED SCRAP AND INCREASED PRODUCT PERFORMANCE YIELDS COST SAVINGS $22,080 Challenge During a line review of a customer’s facility, the Field team noticed a significant amount of product scrap at one workstation. Upon inquiring, the customer informed Field they were scrapping 40 units a day.

Read More

Challenge During an engineering line review of a customer’s facility, the Field team noticed a commonly used, but often unnecessary and expensive fastening method.

Read More

Challenge A customer came to Field with a request for quote on a plastic spacer. Due to potential liability issues, the stability level in this two-piece tank system needed to be increased, without increasing the price per part. Field inquired about the application of the part to ensure optimal design and lowest total considerations.

Read More

Challenge A customer came to the Field team in a panic. A line had gone down due to a part shortage from another supplier, and they needed additional inventory ASAP. Field was able to source this special part within hours, and the lines were back up and running that afternoon. But that was just the start.

Read More